Laser VS sandblasting VS high-pressure water gun rust removal, which one is more powerful?

Dec 10, 2024

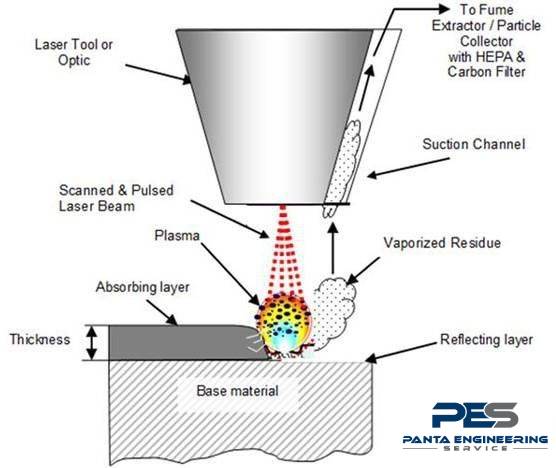

The principle of laser rust removal is laser cleaning.

The process of pulsed Nd:YAG laser cleaning depends on the characteristics of the light pulse generated by the laser, based on the photophysical reaction caused by the interaction between the high-intensity beam, short-pulse laser and the contamination layer. Its physical principle can be summarized as follows:

1. The beam emitted by the laser is absorbed by the contamination layer on the surface to be treated.

2. The absorption of large energy forms a rapidly expanding plasma (highly ionized unstable gas), generating shock waves.

3. The shock wave breaks the contaminants into fragments and removes them.

4. The width of the light pulse must be short enough to avoid heat accumulation that damages the treated surface.

5. Experiments show that when there is an oxide on the metal surface, plasma is generated on the metal surface.

Plasma is only generated when the energy density is higher than a threshold, which depends on the contamination layer or oxide layer to be removed. This threshold effect is very important for effective cleaning while ensuring the safety of the substrate material. There is also a second threshold for the appearance of plasma. If the energy density exceeds this threshold, the cleaning effect will be affected. In order to effectively clean the substrate material while ensuring its safety, the laser parameters must be adjusted according to the situation so that the energy density of the light pulse is strictly between the two thresholds.

Each laser pulse removes a certain thickness of the contamination layer. If the contamination layer is thick, multiple pulses are required for cleaning. The number of pulses required to clean the surface depends on the degree of surface contamination. An important result of the two thresholds is the self-control of cleaning. Light pulses with energy density higher than the first threshold will continue to remove contaminants until they reach the substrate material. However, because their energy density is lower than the damage threshold of the substrate material, the substrate will not be damaged.

Sandblasting Rust Removal

The principles of sandblasting and high-pressure water gun rust removal are actually similar. The main purpose is to spray corundum to impact the surface to achieve the purpose of rust removal. Sandblasting process: It uses compressed gas to spray material (commonly used spray materials include copper ore sand, quartz sand, corundum, iron sand, Hainan sand, etc.) onto the surface of the workpiece in a high-speed air pressure manner. Under the impact and cutting of the spray material on the surface of the workpiece, the surface is given a certain degree of cleanliness (such as rust removal).

Rust removal with high-pressure water gun

High-pressure water gun sprays water and sand together. By combining the lubrication of water and the grinding force of sand, it can effectively remove rust and dirt, while reducing dust and being more environmentally friendly. Rust removal is still difficult without sand. Ordinary cleaning machines cannot complete it. Note that the metal surface needs to be dried in time after the operation to avoid secondary corrosion, and additional equipment may be required to mix water and sand.

Hoe kunnen wij u helpen?